Intralogistics Has Been My Professional Home for More Than 20 Years

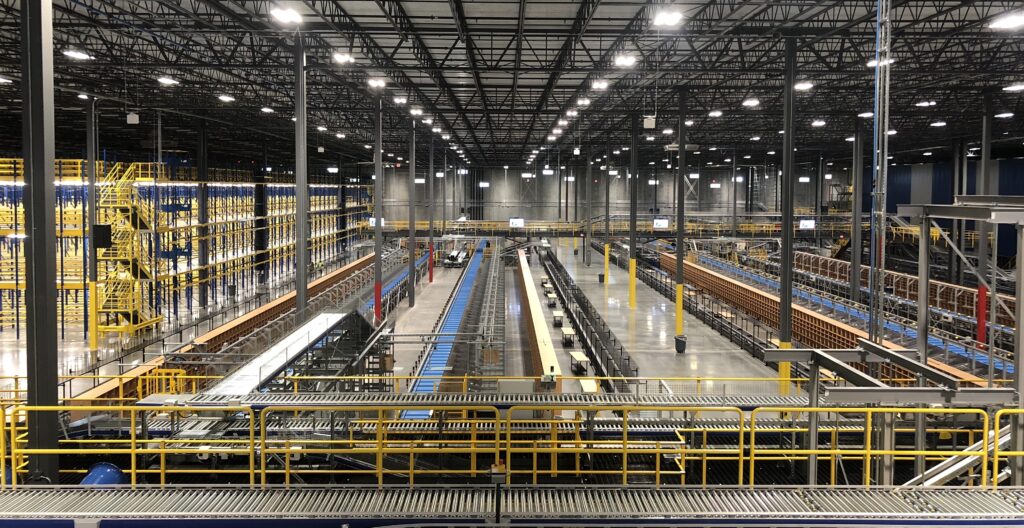

From large automated fulfillment centers to production warehouses and baggage handling systems, intralogistics has been at the center of my entire career. I’ve worked across Europe and North America, leading teams, integrating technologies, and delivering solutions that keep supply chains moving—faster, smarter, and more reliably.

My passion lies in shaping material flow systems that truly work in the real world: robust, efficient, and built around the needs of customers and operations teams.

Core Areas of Expertise

Over the years, I have worked across the most critical building blocks of modern intralogistics:

- Warehouse Automation & Material Flow Design

- Fulfillment & eCommerce Operations

- Production Logistics

- Baggage Handling

- System Integration: Software, Controls & IT

- Project Excellence & Process Optimization

- Operational Readiness & Ramp-Up Management

- Vendor, Customer & Stakeholder Alignment

These areas form the foundation of the solutions and projects I’ve supported and delivered.

Key Projects & Highlights

Below is a selection of projects that shaped my experience and approach.

eCommerce & Retail Fulfillment

Walmart – eCommerce Program (5 Sites)

End-to-end integration of high-volume automated systems, covering storage, picking, packing, and outbound processes. Large teams, tight timelines, and the need for stable, scalable solutions defined this multi-site program.

Lowe’s – Direct Fulfillment Center

Designed and delivered an automated distribution center supporting both store replenishment and eCommerce order fulfillment, including complex material flow and system coordination.

McLane – Ozark Distribution Center

Highly automated fulfillment environment with a strong focus on reliability, performance, and precision. A project focused on complex requirements and long-term operational stability.

Production & Industry

Brose – Automated Production Warehouse

Development of an automated storage and sequencing solution supporting an automotive production environment. Material flow, timing, and accuracy were essential to keep the assembly process running seamlessly.

Aviation Industry

Munich Airport – Terminal 2 Baggage Handling System

Part of the early team supporting software and operations for the baggage handling system at one of Europe’s leading hubs. A fast-paced environment where system uptime and operational readiness are everything.

How I Approach Logistics Projects

My work in intralogistics has taught me that great solutions depend on more than good technology. My philosophy is based on:

- End-to-end thinking — understanding the full flow of goods, data, people, and decisions.

- Practical reliability — designing systems that remain stable under real operational pressure.

- Clear communication — aligning engineering, IT, controls, operations, and leadership.

- Continuous improvement — looking for small changes that deliver long-term benefits.

- Realistic planning — combining ambition with achievable steps and transparent risks.

- Team empowerment — enabling people to make informed decisions and grow through the project lifecycle.

Whether I’m working on project excellence, implementation, or strategic process improvements, my focus is always on building solutions that work—not just on paper, but every day on the warehouse floor.

Technologies & Methodologies

I’ve worked with a broad spectrum of technologies and disciplines common to modern supply chain environments:

- WMS / WCS integration

- Automated storage and retrieval systems (AS/RS)

- Shuttle systems, conveyors, and goods-to-person solutions

- Picking technologies (manual and automated)

- PLC and controls integration

- Material flow analysis and simulation

- Lean & continuous improvement principles

- IPMA-aligned project methodologies

- IT and network infrastructure fundamentals

My background in engineering and IT helps me bridge the gap between operations and technology—a key advantage in complex automation projects.

Outcomes & Achievements

Across my career, some of the outcomes I’m most proud of include:

- Delivering major intralogistics projects for global brands

- Leading cross-functional engineering, IT, and project teams

- Establishing project standards and improving delivery quality

- Supporting successful ramp-ups of large automated systems

- Building processes that reduce risk and increase predictability

- Strengthening collaboration between technical and business teams

These achievements come from many years of learning, adapting, and working with talented people across multiple organizations.

Let’s Talk Logistics

If you’re interested in exchanging ideas about warehouse automation, fulfillment strategies, or project excellence in supply chain environments, I’m always happy to connect.

Feel free to reach out via contact form or LinkedIn.